Tractor Tires and Rims - How to Measure Tractor Tires and Rims in 4 Steps

Tractor Tires and Rims - How to Measure Tractor Tires and Rims in 4 Steps

by Brian Gorney - Tractor Tire Professional

Being able to understand tractor tires and rim sizes should be straightforward and easy, right? If you have ever had to shop for replacement tires and rims for your tractor, you have probably discovered (the hard way) that the subject of equipment tires isn’t quite as simple as you would think. It can be very frustrating for many customers who end up saying to themselves (and sometimes outloud) "I just want a buy a tractor tire and wheel or rim, how hard can that be?" In fact, most people tell me that when shopping for tires online or locally, they often end up with more questions than answers from local tire shops... “What are the rim measurements?” “What is the wheel bolt pattern?” “What is the offset of the wheel?” Honestly, how is anyone who does not size tires and rims for a living supposed to know this information?

Luckily, as a Tractor Tire Pro, this is exactly what I do for a living - it is my job to help people every day find exactly the right tires and rims for their tractor, skid steer, trailers, and every other type of equipment. This article explains, in easy to understand terms, exactly how to measure tires, rims, and wheels to help you find the right fit quickly and easily, every time. After reading this article, you will be able to correctly measure not only tractor tires and rims, but every type other type of wheel and tire just like a pro. If you are ready, let’s get started!

Tractor and Skid Steer Tires and Rims - Introduction

As you may already know, a rim is bolted or fastened to the axle hub on most tractors, skid steers, and other machines that the actual tires mount to. When combined with the tire, it creates what we call the wheel. Obviously, there are many different tires size, therefore there are many different sizes of rims for tire mounting. Tire sizes are most often marked clearly on the side of the tire and are easy to identify. However, if you need a new tire and a new rim for your tractor, machine, or trailer, the tire size itself unfortunately only helps us with half of the answer. To find replacement wheels for your equipment, you will also need to know the rim size and a few other details. These days, most people buy tractor tires online with rims and wheels shipped directly. If you know how to properly measure the rims, when they arrive in 2 to 3 days everything will be a perfect, factory fit.

The 4 Steps to correctly sizing Tires, Rims and Wheels

Step 1: Understanding Tire Sizes

Selecting the right tire and / or tire rim begins with understanding tire itself and the tire size. Depending on the manufacturer and tire application, almost all tires sizes are typically given in either standard size or metric.

Tires Size with two numbers - What they mean

If your tire size has two sets of numbers (10-16.5, 12.4-16, or 18.4R28), here is what the size numbers mean. In our first example of tire size 10-16.5, the first number 10 is the width of the tire in inches. The second number in the example 16.5, is the actual diameter measurement of the wheel that the tire fits. In other words, a 10-16.5 tire is 10” wide and fits a 16.5” rim.

Tire size with three numbers - What they mean

If your tire size has three sets of numbers (18x8.50-8, 31x15.50-15, or 26x12.00-12) here is what the size numbers mean. In our first example of tire size 18x8.50-8, the first number 18 is the total diameter (outside height) of the tire in inches. The second number in the example 9.50 is the actual width measurement of the tire itself. The third number in the example 8 is the measurement in inches of the rim that this particular tire fits. To sum this up, a 18x8.50-8 tire is 18” inches tall, is 8.5” inches wide, and mounts correctly on an 8” diameter rim.

Step 2: Measuring Your Rim / Wheel Width and Diameter

Let’s first begin with the rim width. The method of correctly measuring the width of a tractor tire rim is from inside the bead lip to the inside of the opposite bead lip. Many tractor and equipment owners make the mistake of incorrectly measuring the overall width of the rim instead, which results in buying a new rim that does not fit the tire.

The measurement of the rim diameter is measured the same way. Remember, the rim diameter it is not measured by overall height, but to the first flange (drop) of the bead lip on the rim itself. There are lots of variations of rim sizes and measurements, so again, check that tire size indicating the rim diameter to make sure they match. One helpful tip is many rim manufacturers will stamp the rim size on the on the inside bead flange, which will tell you what the size of that rim actually is. Most times, the rim diameter will be the first digit and the second will be the rim width or class.

Step 3: Understanding and Measuring the Wheel Bolt Pattern

The bolt pattern of a wheel or rim is the pattern of lug holes in the rim where the lug bolts / studs and nuts secure the wheel to the tractor or equipment. The lug holes are the points on the wheel that accept the lug nut or lug bolt to securely fasten the wheel to the equipment. There are always at least three bolt holes in a circle around the large hub hole at the center of the wheel, and many times there are more. The “bolt pattern” specifically refers to the layout and distance pattern that the lug nuts are bolted to the wheel or rim.

To measure the bolt pattern, we first need to count the number of bolt holes that are in (or need to be in) the rim and make sure it matches the axle hub. For our purposes, tractor wheels are most commonly equipped 3, 4, 5, 6 and 8 lug bolt patterns, some less common patterns include 5, 7, 10, 11 or more holes. Once you have determined the quantity of bolt holes, you will next measure the distance between the holes themselves.

Tire rim bolt holes are measured center-to-center, meaning you are measuring the distance between the center (the middle) of the hole the center of another hole. When measuring the distance between the bolt holes on any wheel, it is important to keep in mind that that patterns with an even number bolt holes (4, 6, or 8 holes) are a lot easier to measure than patterns with an odd number bolt holes (3, 5 or 7 bolt holes). We cover how to measure odd hole patterns in a moment.

Even Number Bolt Hole Patterns

To measure patterns with an even number of bolt holes, including 4 bolt, 6 bolt, and 8 bolt patterns, you will measure the distance between the bolt holes directly across from each other in a straight line, again, from center to center of two holes. Record this distance.

Odd Number Bolt Hole Patterns

Patterns with an odd number of holes, like 5 bolt patterns, are more difficult to measure because the bolt holes are not directly across from each other. However, we can still measure them effectively. Begin the measurement by using a straight line from the center of any hole, and measure to where the center of where an opposite hole would be if it were there. Because the wheel bolt hole patterns are in concentric circles, this will give you the approximate correct distance between holes center to center and is close enough for our purposes of hole pattern. Record this distance.

Measuring Wheel Bolt Hole Size

Next, you will measure the size (diameter) of the bolt holes themselves, which vary depending on the size of the bolt or the stud. While a tape measure will work moderately well, I recommend measuring with a caliper instead if you can. Again, a tape measure or ruler will still work and get us a close-enough approximation of the size of the holes for us to identify the correct pattern. Record this number.

Step 4: Understanding and Measuring Wheel Offset

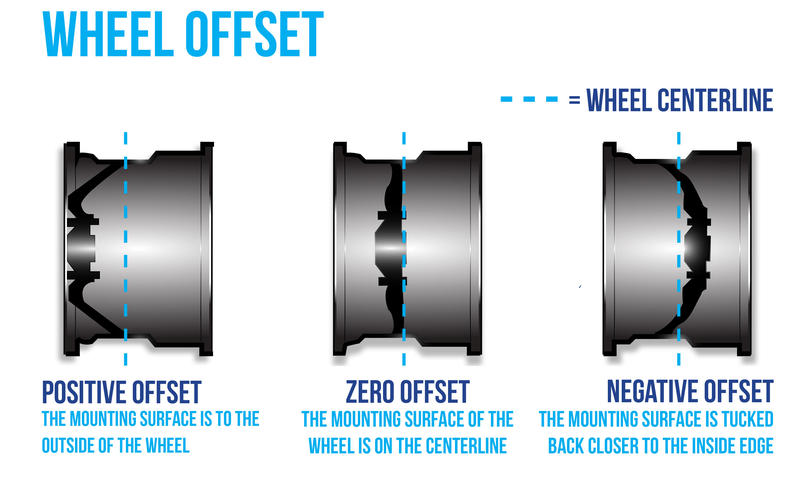

While the bolt holes and center hole of any wheel are located exactly in the center of the wheel (if they were not, a wheel would “hop” as it went around), many people also assume that the mounting point of the wheel to the hub (where the bolts holes are) are placed the same distance (with the wheel vertical and mounted to the machine) from the inside of the wheel to outside of the wheel. While this can be correct in certain cases, most often the wheel bolts and mounting center are “Offset” to be wither closer to the inner or outer edge of the wheel ring when mounted to the machine. This offset results in making the wheel either closer or further away from the axle when bolted to the hub. In other words, the Offset of a wheel or rim is the distance (when vertical or in mounted position) from the vertical center of the wheel to where the center of the rim is when mounted to the hub. This difference in distance when mounted is the Offset measurement, and is referred to as either positive, negative, or zero. Positive offset is when the hub mounting surface is more toward the outside of the wheel, making more of the wheel closer to the tractor. Negative offset is when the hub mounting surface is toward the inside (or hub side) of the wheels, resulting in more of the wheel a further distance from the hub or tractor. Zero offset is when the difference in the mounting surface from the inside and the outside of the wheel is the same (equal).

To measure wheel offset, there are a few steps. First the wheel flat. Second, using a ruler or straightedge, measure the distance from the floor or ground to the top of the wheel and record that measurement. Next, divide that measurement by 2. This result is the vertical centerline of the wheel. Next, measure from the hub flange (where the bolt holes are) to the top of the wheel. If the centerline number is smaller than the hub distance to the top of the wheel, the offset is positive; if it is larger, the offset is negative. Finally, subtract the smaller number from the larger number. That result is the actual offset of the wheel.

Now that you have the wheel width and wheel diameter measurements, bolt pattern measurements, and wheel offset, you are ready confidently buy the correct wheels and tire for your tractor, equipment, or trailer.

More more helpful information, please visit www.TeamTractor.com